why is the vickers hardness test used|vickers hardness test definition : discount store The Vickers hardness test or the 136 degree diamond pyramid hardness test is a microindentation method. The indenter produces a square indentation, the diagonals of . Resultado da Aprende a tocar el cifrado de Receita de Amar (George Henrique e Rodrigo) en Cifra Club. Você vive procurando a fórmula do amor, se entregando de alma e coração / Anda o mundo, se machuca e vê que não passou de um encanto, uma desilusão / Usa meus beijos e

{plog:ftitle_list}

The latest tweets from @manufrogs

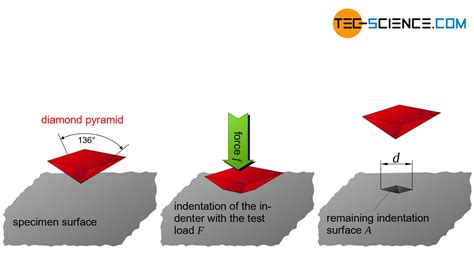

Originally developed by the Vickers Company of the United Kingdom in the 1920s to test alloy armor plates, the Vickers Hardness Test is still utilized to evaluate welded joints and heat-affected zones (HAZ) of metal .The Vickers hardness test or the 136 degree diamond pyramid hardness test is a microindentation method. The indenter produces a square indentation, the diagonals of . The Vickers hardness test is a widely used standard test method for measuring the hardness of metals. It measures the ability of a material to withstand penetration by an . The Vickers Hardness Test is a powerful tool in the field of metallurgy, offering accuracy, versatility, and reliability in assessing a material’s hardness and mechanical properties.

Vickers hardness testing is widely used because it provides accurate and repeatable results for various materials, regardless of their hardness. It's particularly useful for materials that are too hard or too brittle for other .

The Vickers hardness test is esteemed for several reasons: Versatility: It can be used for all metals, unlike some tests that are limited to specific types or hardness ranges. Precision: The .The Vickers hardness test is a method of measuring the hardness of a material by indenting it with a diamond indenter in the shape of a right pyramid with a square base and an angle of .

The Vickers hardness test method, also referred to as a microhardness test method, is mostly used for small parts, thin sections, or case depth work. The Vickers method is based on an optical measurement system.The Vickers method has a test load range from 1 gf according to ISO respectively from 1 gf up to 120 kgf according to ASTM, which means that this method can be used for hardness testing across all load ranges (from the .

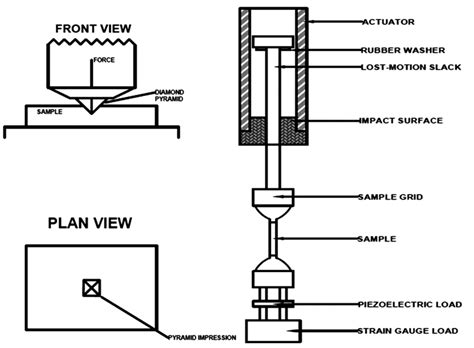

vickers hardness testing machine diagram

Why do Brinell and Vickers Hardness Test Results Show Similarities? For Brinell and Vickers hardness test, the similarities in results often come from the use of an optical instrument to measure the indentation made on the material surface. They both require an optical instrument to measure the indentation to ascertain the hardness values of . When and why is the Vickers test used? HV = 1.854(F/D2), with F being the applied load (measured in kilograms-force) and D2 the area of the indentation (measured in square millimetres). . Why Brinell and Vickers hardness test results show similarities? Explanation: Brinell test indenter is made of hardened steel. Vickers test indenter is made .The Vickers hardness test is more accurate than the Rockwell hardness test because of the use of a microscope to measure the indentation. Cost: The Rockwell hardness test is cheaper and can be used on a wider range of materials, while the Vickers hardness test is expensive because of the optical measurement material used to take the .

The Macro Vickers hardness test It analyzes the hardness of the object by calculating the size of an impression caused by a diamond indenter. This type of hardness test is used for metals and ceramic materials. The test force or load used in the Vickers test is lighter than that of the Rockwell hardness test.

Vickers Hardness Test. The Vickers Hardness Test is a widely used indentation-based method for measuring hardness. It involves pressing a diamond indenter into the material’s surface at a specified load, and the diagonal lengths of the resulting indentation are measured under a microscope.

Rockwell superficial hardness 3. Brinell hardness 4. Vickers microhardness 5. Knoop microhardness 6. Shore Scleroscope hardness 7. Sonodur hardness 8. Mohs hardness 9. File hardness. Describe the Rockwell hardness testing method. It is the most widely used of all hardness testing methods: 1. This method eliminates the effects of small surface . The Knoop hardness test is an alternative to the Vickers hardness test in the micro hardness testing range, and it can be performed on the same universal or micro hardness testing machine. It is mainly used to overcome cracking in brittle materials, as well as to facilitate the hardness testing of thin layers.Hardness testing is a crucial method in materials science and engineering to evaluate the strength and durability of materials, with Vickers and Brinell being two of the most commonly used tests. While each method has its unique applications, there are instances where converting values between Vickers hardness and Brinell hardness is necessary .Why Use the Vickers Hardness Test? The Vickers Hardness Test makes very small indentations on the test sample. This makes it useful for testing very thin materials such as aluminum foils and other microstructures. The Vickers Hardness Test method is very accurate and is fast. The metallurgical engineers can use the test result for rapid process .

Hardness value depends how are you applying the load. If the magnitude of the load is high, the indenter (Vickers or Knoop etc.) will pierce through the outer layer(s) (contamination layer, oxide . The Vickers hardness test can be applied for micro-testing. Knoop: Specifically used to test thin or brittle materials, as it gives a meaningful reading with a shallow indentation. It uses an elongated pyramid to make the impression, with the measurement of the long diagonal used to calculate the Knoop hardness.The Vickers hardness test is a widely used standard test method for measuring the hardness of metals. It measures the ability of a material to withstand penetration by an indenter when it is pressed with a fixed load. You can also use it to measure the indentation hardness of non-metallic materials, provided they are sufficiently dense.There's a lot of total horseshit on google these days, but the wikipedia pages for Rockwell Hardness, Indentation Hardness, etc. don't look too bad, and here is a PDF of a book from NIST about Hardness Testing.The standards for converting values between the different hardness testing methods are governed by ASTM E140 and ISO 18265, which you should definitely buy .

The document describes the Vickers hardness test. It uses a diamond pyramid indenter to make an indentation on the material being tested under a specified load ranging from 5 to 120 kg. The indentation left has a square shape regardless of load. The diagonal lengths of the indentation are measured under a microscope and used to calculate the .The measurement of the depression is used in calculating the Rockwell hardness value. Vickers Test – For this test, a wide range of load is employed making it suitable for measuring the hardness of a variety of material thickness and hardness. The indenter in this case is a pyramid-shaped diamond that utilizes loads from 10gf to 100kgf.Study with Quizlet and memorize flashcards containing terms like Which one is not one of the advantages of hardness test over other mechanical tests? -Hardness being the most important property of the material in design problems -Correlation of hardness value to other properties -Non-destructive -Being cheap to perform, Hardness testing -cannot be used to definitely .Why do some people use Vickers indenters while others use Knoop? Vickers The Vickers hardness test follows the Brinell principle in that an indenter of specific shape is pressed into the test material, the load is removed, the diagonals of the resulting indentation are measured,

The Vickers hardness scale value is presented as HV (Hardness Vickers) and formatted as xxxHVyy/zz, where "xxx" represents the hardness number, "yy" represents the force load, and "zz" represents the load duration. 4. Shore Hardness Test. The Shore hardness test is commonly used for measuring the hardness of soft/hard polymers and elastomers.

These methods of hardness testing are valuable tools in determining “shallow layer hardness,” such as surface hardness, coating hardness, and case depth. Additionally, selective testing of particular grains or constituents could not be performed without these tests. . Although this is true for both Vickers and Knoop testing, Knoop, with .

How Do Hardness Testing Loads Work? Each hardness testing method has a range of loads that are applicable to the use of the test. Some tests, like the Vickers hardness test, can be used on a macro scale as well as a micro scale. The loads required are listed in Table 1 below: Standardized Testing: Vickers hardness testing is commonly used in standardized testing methods, making it suitable for comparing hardness values across different materials. Macrohardness Testing: While primarily a microhardness test, Vickers hardness testing can also be adapted for macrohardness testing of larger samples.Vickers Hardness Testing: Utilises an optical measuring system to measure the area of the impression; Knoop Hardness Testing: Employs a diamond penetrator to impress a sample; . Why Hardness Testing is Essential in Materials Engineering . Hardness testing is a pivotal part of materials engineering, acting as the definitive measure for a .

Welding Hardness test is a type of non destructive test to ensure the integrity of the weld joints. That is performed as per ISO (International Organization for Standardization) standards ISO 9015 and 15614 Specification. But these both standards are not the same, both are used for different purposes. ISO 9015 has two parts, where Part 1 covers hardness testing of arc-welded joints. .HV is a unit of measurement used for the Vickers hardness testing. It represents the value of hardness in terms of depth of penetration under the Vickers scale. It can also be calculated by multiplying the velocity of the tungsten carbide ball that strikes against the test material with its diameter. The calculation uses a standard formula .

The Vickers hardness test, is another popular hardness test method which is named after its inventor George E. Vickers. This is also a quite popular method used for measuring hardness. It employs a pyramid-shaped diamond indenter.The Vickers hardness test is a macro and microhardness testing method, while the Rockwell test is used only as a macro testing method. The Rockwell test is a quick and direct process, while the Vickers hardness test is a slow process and requires other optical devices such as a microscope to measure the hardness of the object. Applications of Brinell Hardness Test: The Brinell hardness test is defined in ASTM E10 is used to calculate Brinell hardness of the metal. It is used on the metal having a rough surface and harsh texture. The Brinell hardness test is used to measure the hardness of light metals like lead and tin, also hard metals like steel and iron. Conclusion:

wd test hard drive

webster aluminum hardness tester

Resultado da 28 de jul. de 2022 · Only Fans Hackeados – Berrorgas. https://fapello.com/anitta/. https://fapello.com/mc-mirella/. .

why is the vickers hardness test used|vickers hardness test definition